Laser Processing

Laser Material Processing System

We have dedicated 3kW Fiber laser (available with CECASE) for cutting, welding, surface treatment and cladding.

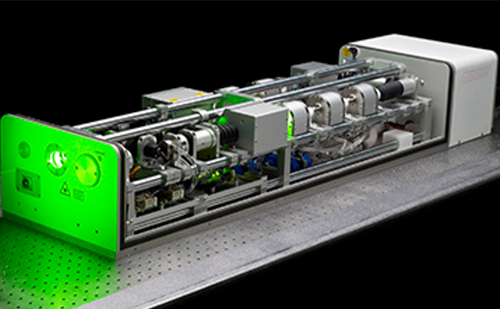

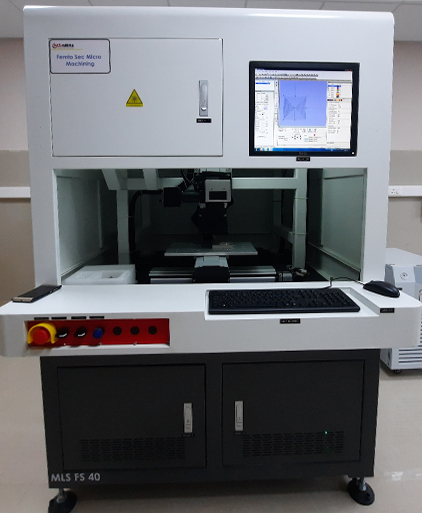

Femto Second Laser Micromachining

The high ablation potential and minimal thermal damage attracts interesting application of femto-second lasers. The 40W femto laser available with CAMA can deliver 350 fs pulses which has tremendous micro-manufacturing scope in multiple industries. The frequency of the beam shall be adjusted between 1 KHz to 800 KHz poised for miniature feature creation. Potential applications include waveguide writing, micro-channeling, scribing, marking, micro hole drilling, surface structuring, micro cutting and dicing. Femtosecond lasers are also used to study laser-matter interactions. We help your research studies that led to the discoveries of a range of highly functionalized materials through high precision laser processing, including metals, alloys, glasses, ceramics, etc., with no heat affected zones, maintaining high accuracy and productivity.

Laser Shock Peening System

The 3.5 J nanosecond laser (available with CAMA) is a unique facility for shock peening to improve fatigue properties, preferably turbine components. With lower repetition rates under 10 Hz, the energy levels can reach GW/cm2. The high compressive residual stresses induced in the material by the generation of high laser pulses is used to enhance the hardness, increase wear resistance and inherently increase the functional life of a component. By this laser shock peening system, fatigue lifetime of components increased by 10 times which ensures components to last much longer especially when working in harsh and demanding environments. This has been mostly used in Aerospace and Power Generation industries to surface treat turbine blades and engine components. The system also have wide applications in spectroscopy, LIBS, LIDAR and PIV.